Specifiche tecniche

Dimensioni

– Dimensione e produttività su misura in base alle esigenze del cliente

– Dimensioni batch sino a 50 T

– Vasche di tempra sino a 400 m³

Componenti linea tipica

– Forni batch

– Vasche di tempra

– Stazioni di raffreddamento libero/forzato

– Stazioni di stoccaggio

– Carrelli di trasferimento

– Caricatrice automatica

Tipi di riscaldo

– Bruciatori a gas a fiamma diretta

– Tubi radianti (atmosfera inerte)

– Resistenze elettriche

Risparmio energetico

– Sistema centralizzato di recupero del calore

– Bruciatori auto-recuperativi

– Bruciatori rigenerativi

– Materiali refrattari di alta qualità

– Monitoraggio continuo tramite sistema di supervisione.

Trattamenti termici realizzati

– Normalizzazione

– Austenitizzazione

– Ricottura

– Solubilizzazione

– Rinvenimento a diverse temperature sino a 800 °C

– Raffreddamento in diversi fluidi: (acqua, polimero, olio)

– Ricottura isotermica con stazioni di raffreddamento indiretto

Standard di uniformità della temperatura

– API 6A

– AMS2750E (Aerospaziale)

– NORSOK (Oil and gas)

– CQI-9 (Automotive)

Sistema di supervisione dei trattamenti termici

– Sistema di supervisione su misura connesso al gestionale del cliente.

Linee automatiche batch

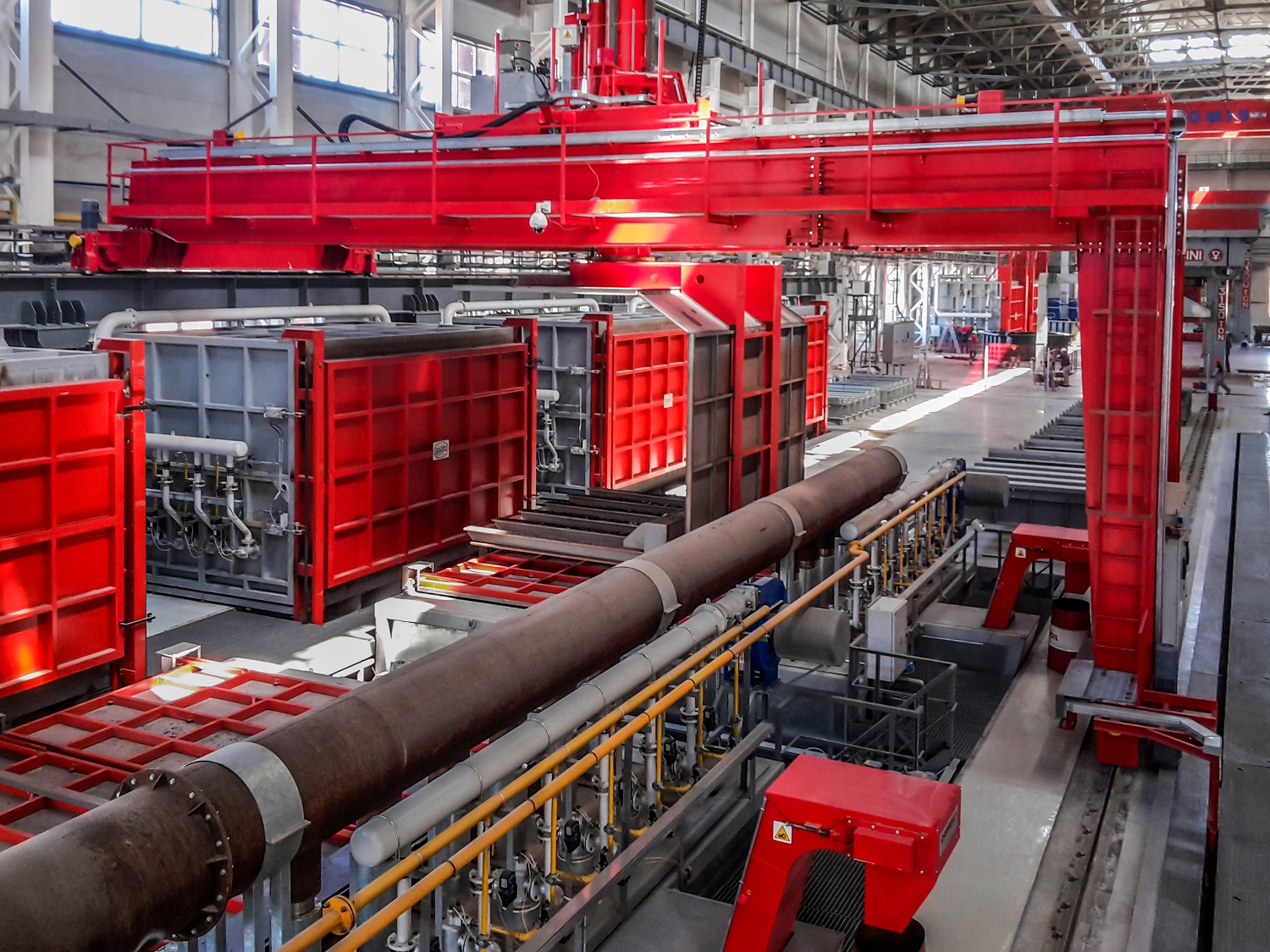

La progettazione e produzione di linee automatiche batch è il core business di Gadda group. Le linee includono le macchine necessarie all’esecuzione del ciclo termico desiderato: forni di austenitizzazione, forni di rinvenimento, vasche di tempra, macchine per la movimentazione della carica, stazioni di raffreddamento libero/forzato, stazioni di stoccaggio e le attrezzature di movimentazione/trasferimento.

Le linee di trattamento termico sono completamente automatiche, tutti i processi vengono gestiti da sistemi di controllo computerizzati. Con adeguate stazioni di stoccaggio del materiale, è possibile produrre in continuo senza supervisione diretta oppure durante i fine settimana. I progetti sono realizzati su misura per meglio rispondere alle esigenze dei clienti.

I materiali tipici trattati sono molteplici: barre, tubi, giunzioni, pezzi forgiati o stampati. Le linee batch sono molto flessibili e coprono quasi ogni trattamento termico eseguibile. Un approccio modulare permette un’espansione futura per soddisfare le necessità di aumento di produzione.