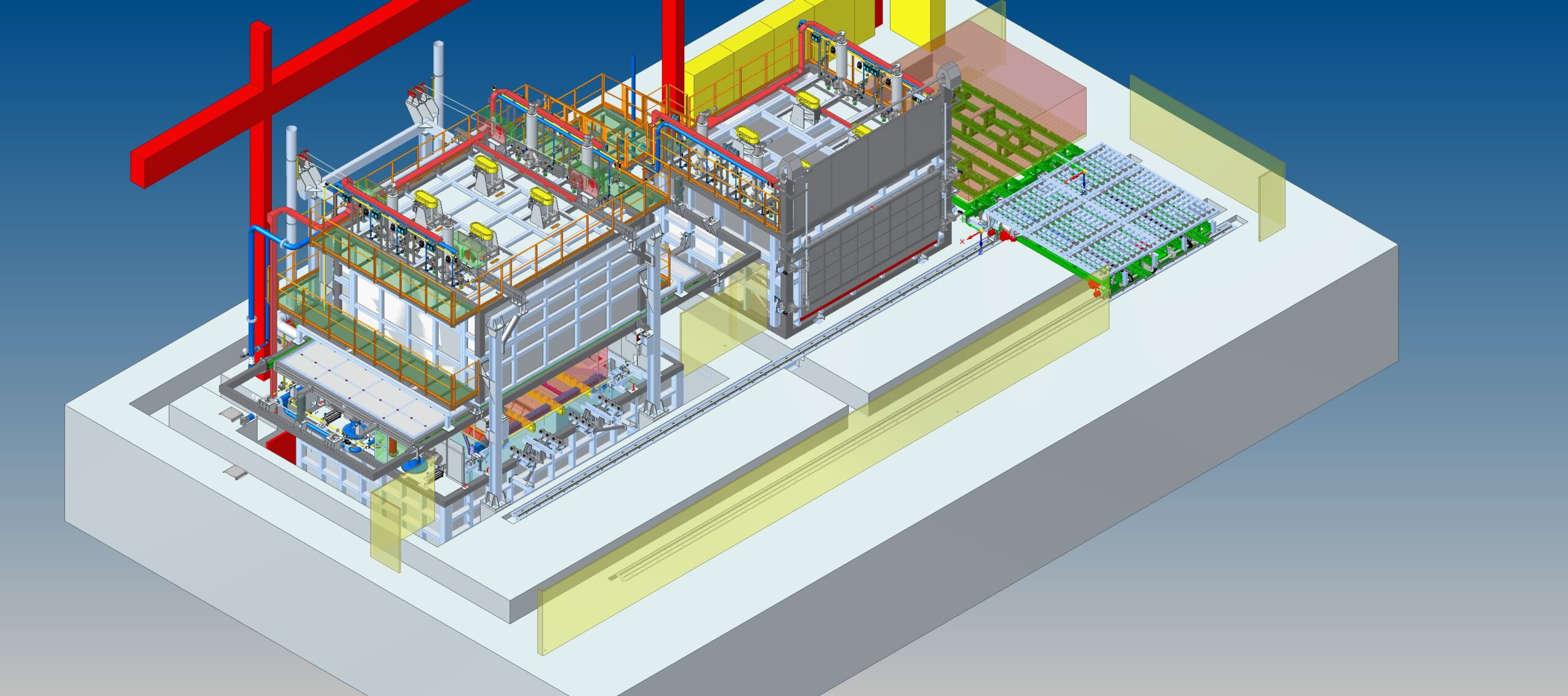

Automatic Batch Line #1384

The Automatic Batch Line for the treatment of T6 light alloys consists of:

– 1 charge preparation station with weighing cells

– 1 automatic loader

– 1 solution furnace “drop-bottom”

– 1 cooling tank in thermostated water

– 1 ageing chamber furnace

The uniformity performances were achieved thanks to dedicated fluid dynamics studies for each furnace. The cycles repeatability is obtained thanks to the automation system installed, capable of autonomously managing the operation of the plant. The furnaces are all pre-assembled and tested in our workshop.

This 4×4 metre automatic batch line is a custom-built plant. The operator only needs to place the batch in a dedicated area: the loader then takes care of all the operations, from loading the solution furnace to unloading, including water cooling and loading the ageing furnace, until the treated batch is returned to the unloading area.

For aluminium alloys, AMS2750 standards require Class 1 temperature uniformity (+/- 3°C) and very fast shutdown times of less than 15 seconds. Our experience in low temperature heating and thermo-fluid dynamic analysis has enabled our engineering team to develop a product that meets these complex requirements. Despite the large working area of 28m3 with 30 TUS thermocouples, we have achieved temperature uniformity below Class 1 (see the graph below).

Batch Automatic Line #1384

Charge’s net weight

7500 Kg

Temperature

150°C – 300°C (ageing) 400°C – 580°C (solution)

Overall specifications

- Charge size: 4800mm x 4800mm x H1250mm

- Charge’s net weight: 7500Kg

- Working temperatures: 150°C – 300°C (ageing) 400°C – 580°C (solution)

- Temperature uniformity: +/-3°C AMS 2750F class 1

- Shutdown time <= 15s from the start of door opening until complete immersion

- Electric/Gas heating system