Technical specifications

Dimension

– Size and productivity tailored to customer needs

– Batch sizes up to 50 T

– Quenching tanks up to 400 m3

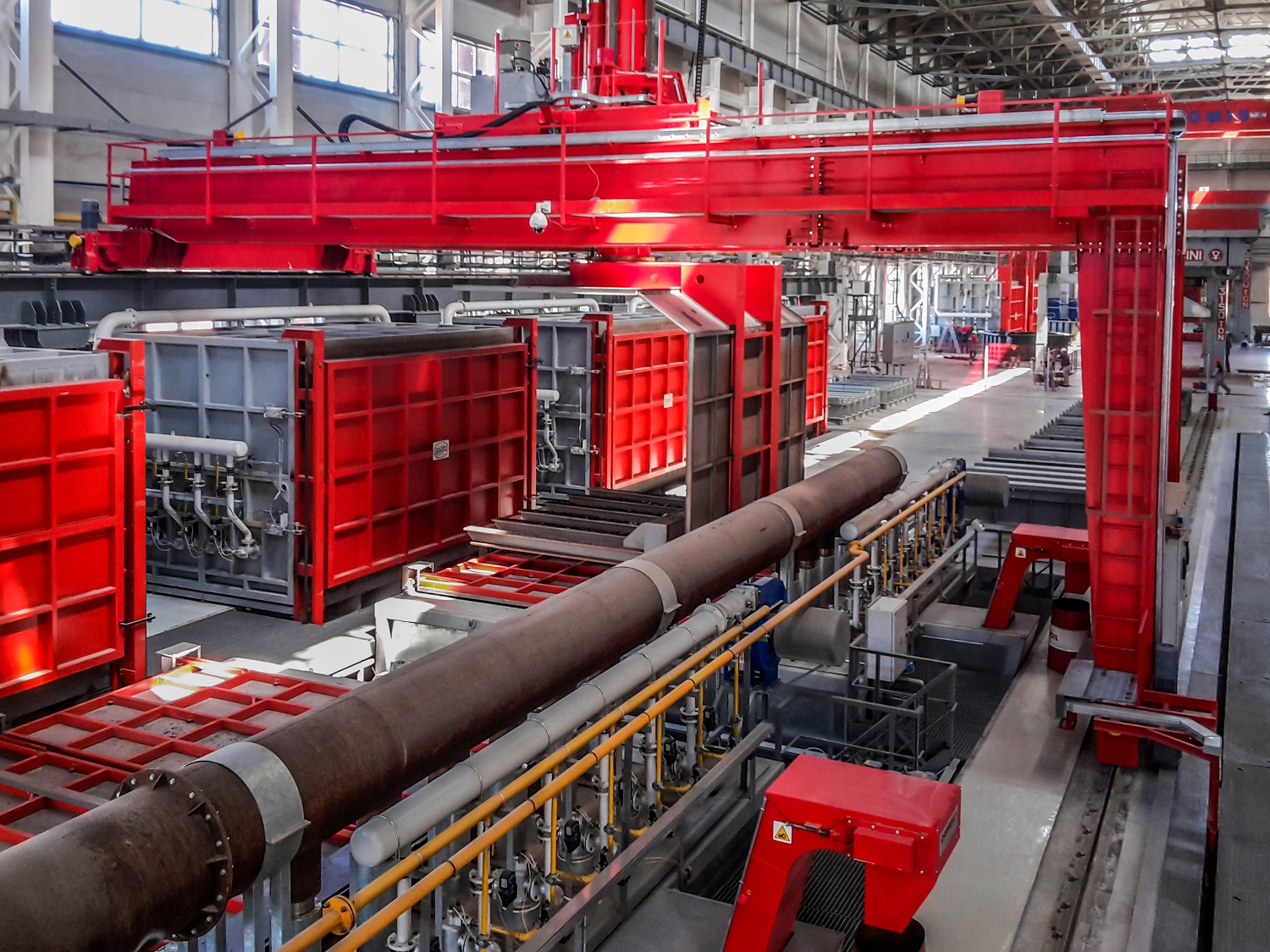

Typical line components

– Batch furnaces

– Quenching tanks

– Cooling stations

– Storage stations

– Transfer trolley

– Automatic loading machine

Heat treatment types

– Gas burners direct flame

– Radiant tubes (inert atmosphere)

– Electric heating elements

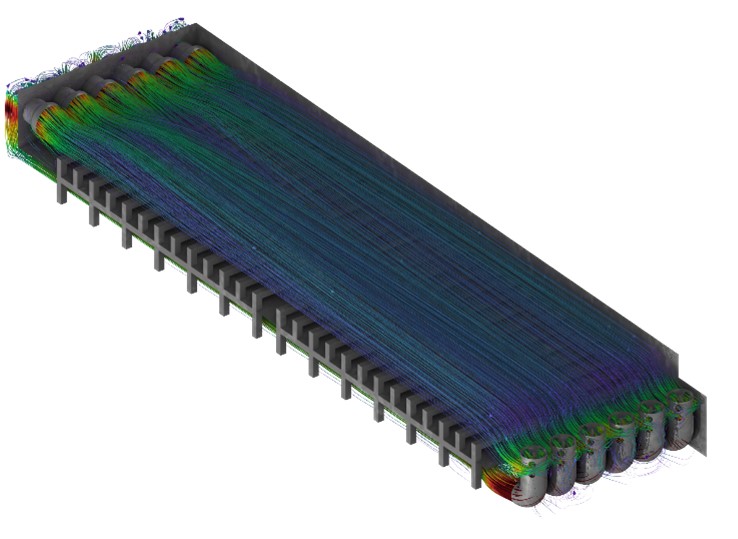

Energy saving

– Centralized heat recovery system

– Self-recuperative burners

– Regenerative burners

– High quality refractory materials

– Continuous monitoring through supervision system

Heat treatment performed

– Normalizing

– Austenitizing

– Annealing

– Solubilization

– Tempering at different temperatures up to 800 °C

– Quenching in different fluids: (water, polymer, oil)

– Isothermal annealing with indirect air-cooling stations

Temperature uniformity standard

– API 6A

– AMS2750E (Aerospace)

– NORSOK (Oil and gas)

– CQI-9 (Automotive)

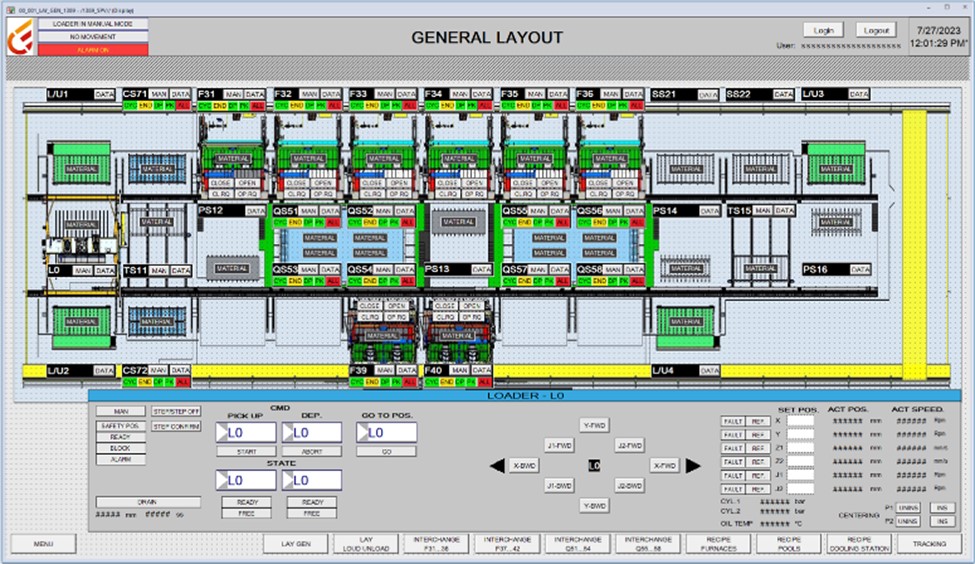

Supervision system

– Custom made supervision system ready for full integration with customer management system

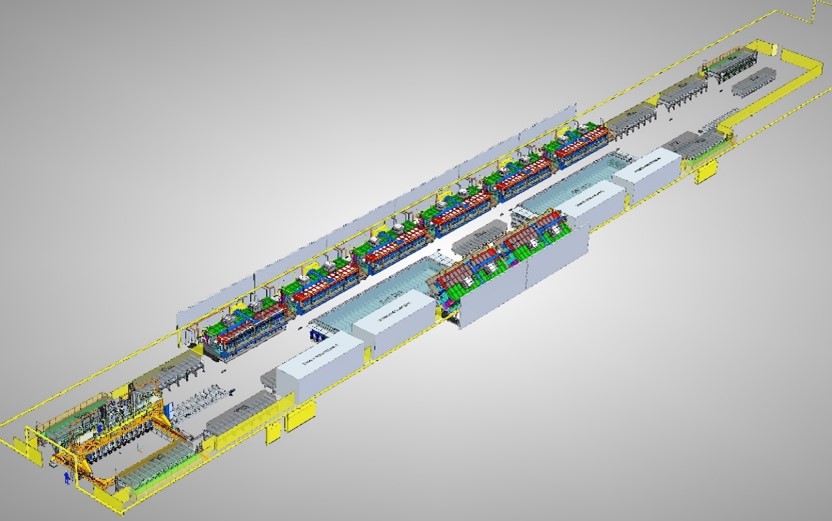

Batch Automatic Lines

Batch automatic lines represent Gadda’s core business. Each line could include: austenitizing and tempering batch furnaces, quenching tanks, loading/unloading machines, cooling stations, storage stations and handling equipment.

Heat treatment lines are fully automatic, all processes are controlled by the computerized control systems and with adequate storage stations, customers can perform continuous production without supervision or during weekends. Projects are tailored to best satisfy customers requirements.

Typical materials treated are: bars, alloyed steel pipes, fittings, forged or cast pieces. Batch lines are very flexible and cover almost any executable thermal treatment. A modular approach allows future expansion to accommodate incremented productivity needs.